Exploring the world of Innovative Design Products: How advanced plastics are redefining the modern world?

Blog

Exploring the world of Innovative Design Products: How advanced plastics are redefining the modern world?

Authored By: SDI Plastics

Plastics have become an integral part of product design and manufacturing across industries. From consumer electronics to automotives, healthcare devices to energy systems, plastics are pioneering innovative design products and redefining modern products. Advanced plastics, such as high-performance polymers, elastomers, bioplastics, and nanocomposites, are enabling lighter, stronger, more durable, and more sustainable products.

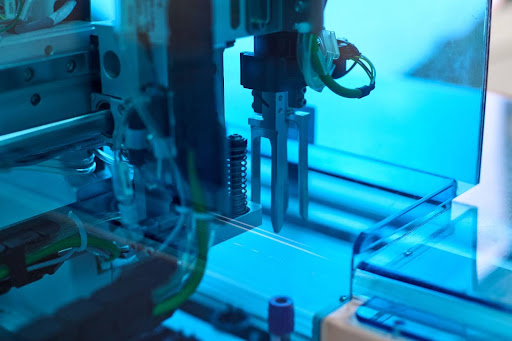

With customisable mechanical properties, enhanced aesthetics, and ease of processing, advanced plastics allow the design of novel products with an improved user experience. Plastics also facilitate versatile processing techniques like injection moulding, 3D printing, and thermoforming to create intricate product geometries and features otherwise unfeasible with traditional materials.

Here we will explore key advanced plastic types powering new product development and their transformational impact across the consumer electronics, automotive, and healthcare industries.

With a growing shift towards recyclable and eco-friendly solutions, plastics are gearing up to build a more sustainable and smarter future.

Increased use of plastics in innovative product design across industries

Plastics have emerged as wonder materials for designers and engineers with their unparalleled versatility, customizability, strength-to-weight ratio, enhanced functionality, and sustainability. As a result, plastics have been rapidly replacing metals, glass, and wood in everything from packaging to structural components and critical electronics.

Plastic production witnessed exponential growth in recent years in sync with their rising adoption across industries: 442 million metric tonnes of plastics were produced globally in 2023 alone. Automotive and electronics are leading the consumption of engineering plastics, together accounting for over 40% of the total high-performance plastics demand.

The development of advanced materials, additive manufacturing, and reinforcement materials have all contributed to the increased use of plastics.

- Advanced plastics enable lighter, stronger, and more durable products.

- Sustainable bioplastics are also gaining traction.

- Plastics are pioneering innovation and redefining modern products.

Key plastic types powering new product

High-performance polymers: Polymers like polyether ether ketone (PEEK), polysulfones, polyimides, and liquid crystal polymers are pushing the boundaries of high heat, chemical, and wear resistance in plastics. With their strength rivalling metals, these are widely used in automotive parts, electronics, aerospace components, medical devices, and energy systems like wind turbines.

1. Elastomers

Thermoplastic elastomers (TPE) made of plastic and rubber offer rubber-like flexibility and elongation similar to thermoset rubbers, while also allowing the recyclability of thermoplastics. Silicone elastomers provide extreme temperature stability, making them suitable for automotive and aerospace applications.

2. Bioplastics

Derived from plants or other renewable sources, these eco-friendly plastics offer similar mechanical properties as conventional plastics. Polylactic acid (PLA) and polythene furanoate (PEF) are popular examples of sustainability, especially in packaging.

3. Nanocomposites

Incorporating nanoscale reinforcement into plastics imparts substantial improvements in strength, heat resistance, and other mechanical properties, allowing lightweighting. Carbon nanotubes, graphene, and nanoclays are popular choices.

These advanced plastic types enable tailoring mechanical properties like strength, chemical resistance, heat range, durability, and weight based on product requirements and environments.

Trends indicate a widening adoption of high-performance thermoplastics over metals and thermosets. Bioplastics and nanocomposite adoption is also expected to grow significantly to drive sustainability and lightweight further.

Advanced plastics in consumer electronics

From displays to internal components, plastics have become ubiquitous in today’s consumer electronics like smartphones, tablets, wearables, and laptops. With lightweight, durability, enhanced aesthetics, and design flexibility, advanced plastics are enabling performance improvements alongside slimmer and more compact product designs in electronics.

- Plastics make up the external casings, buttons, and lenses in handheld devices, as well as internal parts like electric wiring insulation, connectors, and printed circuit boards.

- High-performance polymers withstand repeated drops and accidents, thereby extending their lifespans.

- Flame-retardant plastics also mitigate risks from overheating or short circuits within dense, compact product packaging.

- Additional properties like ductility, vibration dampening, EMI shielding, and noise reduction aid functionality. Their poor thermal conductivity helps retain internal heat for components without the need for extra insulation.

Advanced plastics further expand the horizon of electronics innovative design products with the increasing integration of flexible and stretchable components, transparent electronics, sensors, antennas, and other smart devices. Lightweight composites, bioplastics, and flexible materials enhance the user experience while boosting sustainability and recyclability targets.

For example, Samsung’s Galaxy phones sport a sleek, glossy plastic exterior that is also more durable and scratch-resistant than their glass counterparts, while reducing both product and carbon footprint.

Apple transitioned to using 100% recycled rare earth plastics in their products, pushing the boundaries of sustainable innovation. Thus, advanced plastics offer a blend of form and functionality to elevate product performance alongside the user experience.

Revolutionising the automotive industry

In automotive engineering, advanced lightweight plastics open up worlds of possibilities, allowing radical rethinking of designs focused on efficiency and carbon footprint reduction. They now make up almost 50% of a car’s volume but just 15% of its weight.

High-performance thermoplastics have nearly universally replaced metals in interior and exterior plastic body panels, bumper fascias, and fuel systems. Engineering plastics are moulded into intricate shapes not feasible with steel stamping, with chemical, scratch, and temperature resistance suitable for under-the-hood applications.

Automotive plastics can further be customised with modifiers for UV stabilisation, flame retardance, conductivity, and even visual effects like metallic finishes or self-healing capabilities. Carbon fibre-reinforced plastics (CFRPs) and lightweight composites bolster efficiency, cutting down overall vehicle weight and emissions significantly.

Beyond manufacturing, plastics unlock innovations in product performance, safety, and styling. As lighter components increase EV battery ranges and fuel economy, silicones boost insulation, and polymers augment impact resistance, improving passenger safety.

Plastics also enhance comfort with properties like sound dampening, customised colours, and lighting. Self-driving vehicles feature an array of sensors and radar, with plastic housings seamlessly merging aesthetics with functionality.

Companies are now focusing on recycling or alternative raw materials through innovations like CO2-based foams for an even lower carbon footprint. Thus, plastics accelerate the vision towards a lighter, highly efficient, customised, and autonomous automotive future.

Plastic breakthroughs in healthcare

Advanced medical-grade plastics are the workhorses empowering state-of-the-art healthcare solutions, from life-saving medical devices to futuristic drug delivery systems and artificial organs. Their biocompatibility, cost-effectiveness, chemical and thermal stability, coupled with their lightweight, strength, and precision processing, make plastics indispensable across medical innovations.

High-performance polymers, elastomers, and composites like PEEK, acrylics, polycarbonate, nylon, and silicone enable the engineering of next-gen pacemakers, catheters, implants, and surgical tools. 3D printing further leverages these materials to manufacture patient-specific products and prosthetics.

Sterilisability and biocompatibility tailored as per required organ/tissue contact expand plastics adoption in short- or long-term life-critical devices. Synthetic skin materials and fillers aid in healing and cosmetic procedures. Self-healing plastics also assist in reductions in healthcare costs and follow-ups.

Microfluidics technology for moulding tiny channels in plastics led to historic revolutions in point-of-care diagnostic devices, lab-on-a-chip detection, and high-throughput drug screening systems, transcending traditional bulky healthcare systems.

Further breakthroughs enabling shrinking clinical labs onto a plastic chip include organ/disease-on-a-chip platforms and non-invasive tools for personalised diagnostics and targeted therapy. The role of plastics thus extends from improving quality of life to saving lives daily around the world.

The future with smart and sustainable plastic solutions

While plastics underpin product innovation across industries, environmental sustainability is a key focus area in their future. Recycling plastics could hold the key to unlocking their full potential for quality, performance, and self-sufficiency through a circular production economy. This has driven significant materials chemistry research to develop advanced recycling and biodegradation solutions for plastics.

Mechanisms like polymer upcycling to convert used plastics into higher-quality materials also show strong promise. Most major polymer manufacturers, like LyondellBasell, and consumer brands, like HP Inc., have already pledged recycled content utilisation targets by 2025 and are redesigning product lines targeting circularity. Flexible bioplastics also continue to garner interest as potential substitutions gradually ramp up in scale.

Furthermore, with the increasing integration of the Internet of Things (IoT), plastics are gearing up to power smarter, multi-functional products.

Plastics, being inexpensive and versatile substrates for printed electronics, sensors, chips, and antennas, will drive the expansion of smart plastic use cases. Lightweighting demanded across renewables and electric mobility implies high-performance plastics hold the future.

In addition to bolstering industry sustainability targets through recyclability or bio-based alternatives, they continue pushing the boundaries of customised product personalisation and performance.

Be it haptic feedback, textured finishes, shape memory, or other stimuli-responsive plastics on the rise, there are still infinite possibilities left to tap into by designing advanced plastic solutions that uplift products as well as the planet.

Conclusion

In summary, advanced plastics underpin innovative design products and disruptive technologies across sectors while steering the sustainability drive. Their unparalleled tunability, processability, and diverse property profiles power the creation of novel, high-efficiency, and circular products, redefining existing benchmarks.

Lightweighting, enhanced safety, and sustainability goals, coupled with expanding smart functionalities, demand for customisation, and an improved user experience, will catalyse the development of superior plastics and composites.

Materials chemistry breakthroughs to balance performance and green credentials remain imperative for future-proofing plastic technologies to uplift lifestyles while conserving resources.

With the increasing adoption of high-performance thermoplastics, reinforced polymers, nanocomposites, bioplastics, and recycling solutions, plastics hold immense promise to transform the modern world.

Book your free consultation

Give us a call to book your free consultation and learn how much value can be added to your business with SDI Plastics by your side.