CNC Machining and its importance in the manufacturing process

Blog

CNC Machining and its importance in the manufacturing process

Authored By: SDI Plastic

CNC machining is a manufacturing process in which pre-programmed computer software controls the movement of factory tools and machinery. The method handles various complex machinery, including grinders, lathes, mills, and CNC routers. Three dimensional cutting tasks can be completed using CNC machining services in a single set of prompts.

The workpiece is utilised in CNC manufacturing, and the machine dispenses with layers of the workpiece to form the result. This CNC cutting process is appropriate for many materials, including metal, composites, glass, plastics, to name a few. Due to its speed and accuracy, this manufacturing technique is used in various industries, including construction, aerospace, automotive and others. The custom CNC machining process incorporates several machining processes, including chemical, electrical, and thermal.

What is CNC Manufacturing exactly?

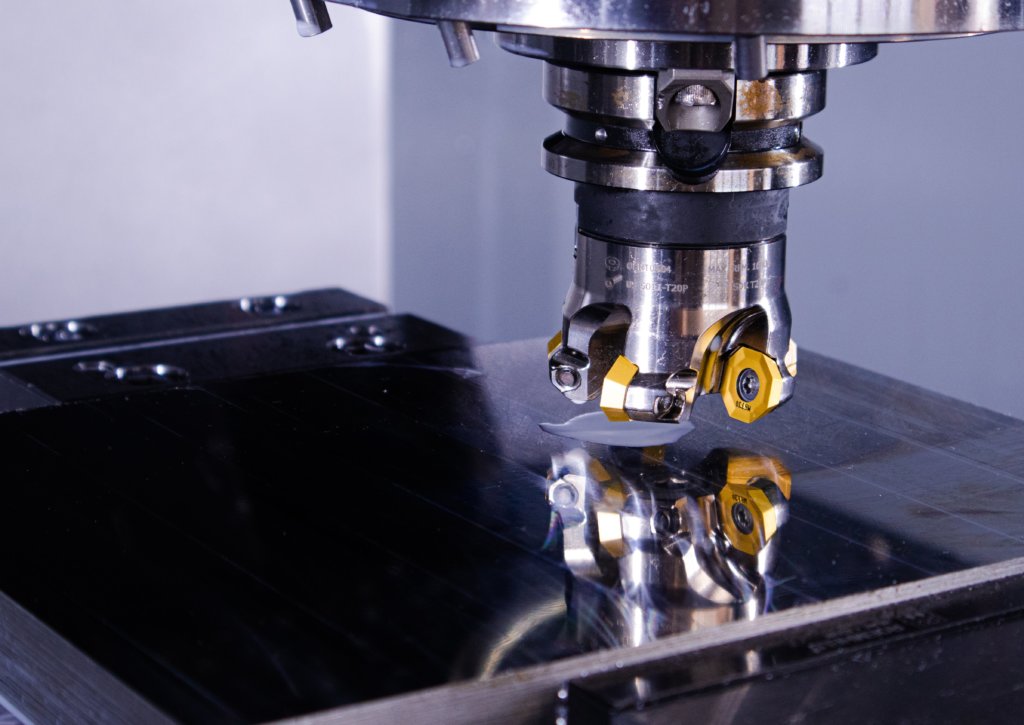

CNC machining is a subtractive manufacturing technology, meaning that the end product is formed by selectively removing excess material from the workpiece. In CNC, material is removed from a solid block using a variety of cutting tools that rotate at high speed, at thousands of RPM, to produce a part based on a CAD model. Both metals and plastics can be CNC machined.

Every CNC machining operation follows the same four step production process.

These four stages of production are as follows:

Design of a part

CNC machining parts are typically created from initial designs created with Computer-Aided Design (CAD) software. Computer-aided design or CAD is the use of computers to help the formation, modification, function, analysis, or application of your design. During the design phase, engineers carefully consider all angles of the required product and the parameters required to build the final product.

Conversion of design

After the initial design phase, the CAD model must be converted into a functional CNC program using Computer-Aided Manufacturing (CAM) software. CAM software can extract geometrical requirements from the origin file of a CAD model and translate them into a CNC-compatible programming language, such as G-code or M-code, which will dictate the machine’s mechanical operations.

Preparation of CNC Machines

The CNC machine operator must then configure the machine and the target material to the CNC program’s specifications. The operator will ensure that the proper cutting or drilling tools are installed and matched with the correct bits or end mills. The workpiece must also be set up in a stationary clamp or directly attached to the CNC machine by the operator.

Execution of planned operations

Finally, the CNC machine operator carries out the necessary mechanical processes. During operation, the CNC program precisely controls the machine tooling movements.

The advantages of CNC Machining

CNC machining provides many competitive advantages, including:

- Orders are processed quickly

- High accuracy

- Highly adaptable

- Produces products with outstanding physical properties and performance thresholds.

CNC operation types

CNC machining services cover a wide range of industrial jobs, improving accuracy and completing the work in less time. The CNC operations are as follows:

Drilling with a CNC: It uses a multiple-point setup to drill cylindrical holes in the workpiece during the drilling process. The drill is produced perpendicularly to the workpiece’s surface by the machine. The engineer can design vertical holes with variable diameters depending on the job.

The CNC machine can also drill angular holes, but this requires a specialised bespoke setup before the holes can be produced. Therefore, relying upon counterboring, countersinking, and other CNC drilling operations is popular. As a result, CNC drilling is more accurate and has a faster turnaround than traditional processes.

CNC Milling: The machining process involves using multi-point rotating cutting tools on the machine to remove material from a piece of metal or other material. The device inserts the blank piece into the cutting tool in the same direction as the tool’s rotation in milling. It differs from the manual process in that the machine inserts the material block in the opposite direction. Some general operations of CNC milling include cutting shallow, creating flat cavities, peripheral milling, producing deep pits, and more. Threads and slots can also be made using the CNC milling process. Furthermore, we offer professional assistance to improve job accuracy and quality of CNC machining throughout Brisbane, Sydney, and Melbourne, Australia.

CNC Turning: In CNC turning, the machine removes material by cutting it with a single point operational tool. The engineer employs a turning machine or a lathe in this process. In a linear motion, the CNC machine feeds the cutting tool into the workpiece, removing material from the external boundary. This procedure is repeated until the desired diameter is achieved. This method is used to create cylindrical parts with both external and internal features.

Applications for CNC Machining

CNC machined parts are used in a wide range of industrial applications, and SDI Plastics have the ability to provide services to a wide range of industries.

CNC machining is highly automated

The production of parts using pre-programmed software is primarily automated in today’s CNC protocols. Computer-aided design (CAD) software sets the dimensions for a given number, which is then converted into an actual finished product using computer-aided manufacturing (CAM) software. To meet these demands, many modern machines combine multiple functions into a single cell. Alternatively, an installation could include several machines and a set of robotic hands that transfer parts from one application to another while being controlled by the same program. Regardless of the configuration, the CNC process ensures consistency in part production that would be difficult, if not impossible, to duplicate manually.

SDI Plastics is the preferred place for your CNC machining needs

SDI Plastics is the place to go when you need the best CNC machinery requirements in Australia.

Request a quote today to understand more about our CNC machining services and work with us on your next project. You can get started quickly by connecting with the SDI Plastics team on (07) 3807 8666 for CNC machining services.

Book your free consultation

Give us a call to book your free consultation and learn how much value can be added to your business with SDI Plastics by your side.