Industry Insights

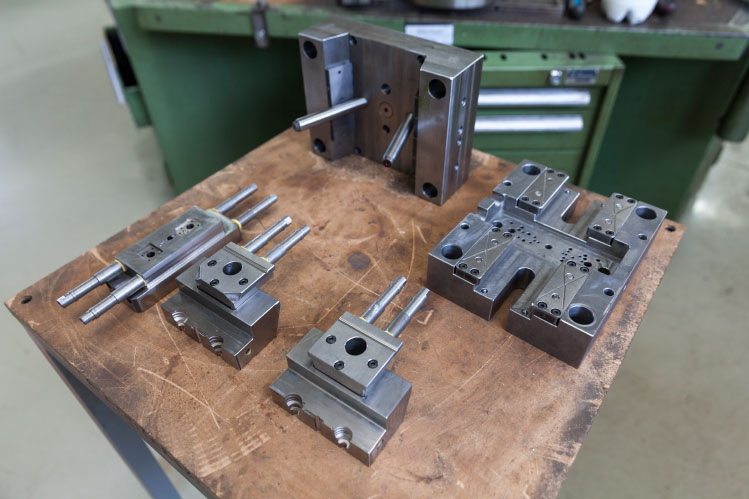

Injection moulding toolmaking

The injection moulding tool is the heartbeat of the injection moulding process.

Without a correctly made tool any injection moulding process can run into trouble. This is why at SDI Plastics we ensure that all out tools are made with the utmost care and attention. Every step of the process is thoroughly checked to ensure errors are eliminated or minimised.

Many people ask, “what is the injection moulding tool?” and it’s a valid question. Unless you have prior knowledge of the injection moulding process then it is hard to know what some of the terminology in the industry means.

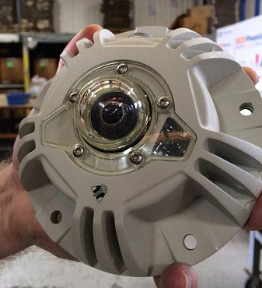

In a nutshell, the tool is a reverse engineered void in the steel mould that produces the part. Every tool comprises of two halves, one fixed and one moving. When these halves are joined together, they form the mould. Molten plastic then gets injected into the mould, which is held together by high clamp pressure (from the machine). This is the process, which creates the final plastic product.

There are a several components of the tool that each have different functions and all act together like a well-oiled Swiss watch. They can include:

| Fixed half | Hydraulic motors |

| Moving half | Hydraulic slides |

| Hot runner systems | Hydraulic cores |

| Backplates | Threaded cores |

| Ejector pins/Air cylinders | Sliding cores/Cooling channels |

The fixed half remains fixed on the machine, and is where the molten plastic begins entering the mould. After the injection of the plastic is completed, the moving half separates away from the fixed part of the mould, allowing the parts to be ejected away and continue the process until the production desired quantity is reached. Ejectors separate the products from the mould by the below processes, depending on the tool design:

- Ejectors to eject the part off the mould

- Hydraulic motors to unscrew a thread

- Stripper plates to strip the part off the mould

- Air ejection

At SDI Plastics we make our tools from high-grade “tool quality” steel. High-grade steel is required as in most cases, the injection and clamping occurs under high pressure. Aluminum tools can be used for creating the prototypes or very low volume products; however, extreme caution must be used when using this process.

The truth is that tools are essential to the injection moulding process. You cannot make a plastic part without the tool/mould.

Is it possible to buy the tools ready made?

Whilst it would be great to be able to buy the tools ready made, the fact is that because the injection moulding process is so intricate, each tool must be specifically designed and made individually. Off the shelf products are not available.

Each customer has their own unique requirements and product uniqueness. Most tools/moulds are made with a high amount of secrecy and intellectual property as a distinct competitive advantage. This ensures that when a product is brought to market it is given the highest chance of success.

Is the injection moulding toolmaking process hard?

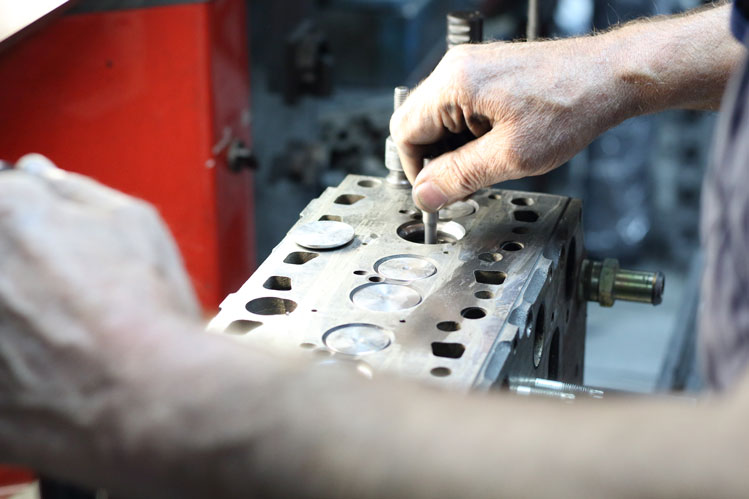

Yes – injection moulding toolmaking is difficult and involves high precision work. The process requires extensive knowledge and understanding of the intricacies involved in tool making and plastic moulding. A poorly made mould can result in lost production time, poorly made parts and in some cases can result in field failures.

There are companies who create tools where each of their workers follow certain processes to create only one specific part of the mould. This is a very haphazard way to go about toolmaking and can lead to complications down the track. At SDI Plastics, our toolmakers understand the true art of tool making and build an entire mould from scratch using a block of steel.

What is involved in the tool making process?

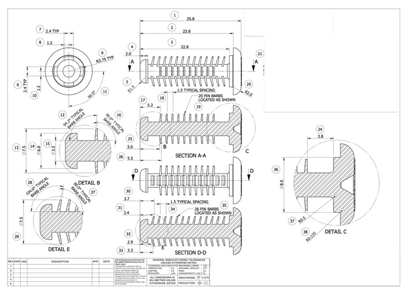

The tool making process starts with a tool set and each section is virtually a block of steel. The toolmaker then machines the plates individually according to a specified drawing to create the components that make up the tool.

Once to the tool is complete and first production samples are produced, the toolmaker then measures all components to ensure they meet their specifications before undergoing final adjustments and in some cases the final stages of polishing. The time to polish the part depends on the required finish. For example, a mirror polish can take weeks whereas a rough polish can be achieved in a much shorter timeframe.

To avoid damaging certain parts of the tool, some customers also prefer us to pre harden the steel using a pre-hardening process. This can extend the life of the mould and is one option that is available.

How much will the toolmaking cost?

The cost of toolmaking varies for each project, dependent on project requirements. Before starting any project we will meet with you and discuss your specifications and make any suggestions we feel may help.

We will then cost the job and send you a written proposal for your consideration.

At SDI Plastics, we don’t cut corners to build our tools. In some cases it might be cost prohibitive when compared to our competitors, however it can save you in the long run as you can be guaranteed of the highest quality tool that causes minimal disruption during the production phase.

How long will the tool last?

The life span of the tool depends on a number of factors including the specification of the mould, the type of material used to create the product and how it is handled.

You can expect our tools to last the years – Our oldest tool is 35 years old!

Let’s work together

Give us a call to book your free consultation and learn how much value can be added to your business with SDI Plastics by your side.