Industry Insights

The circular economy approach

Energy conservation, natural resources and recycling are essential components for sustainable manufacturing. In addition a key area of focus is moving away from a linear economy and towards a circular economy for plastics. The implementation of the “circular economy” is a model where all plastic packaging is 100 per cent ‘reused, recycled, or composted’, whilst the linear economy is ‘take, make, dispose’, which is how many organisation’s operate with a lot of materials and resources.

SDI Plastics adopt the circular economy approach, working with our team and our clients to eliminate waste, be energy efficient, promote reusable packaging, plastic recycling, initiating environmental sustainability in manufacturing, building smart offices, to focus on community and society wide benefits whilst also actively preserving the environment.

Recycling and repurposing plastics

While plastics has many positive contributions in the world, a commonly asked question by our new clients and partners is around the use of recycling plastics in our injection moulding facility.

Plastic wastage is a problem globally, not forgetting our oceans, and SDI Plastics is taking this problem seriously. We are happy to say more clients agree to use a recycling component as part or all of their product matrix. Our business is tackling this problem through various initiatives to prevent further pollution in our oceans and waterways.

Recycling best practice

The plastic injection moulding process forms a waste material called ‘runners’. Runners are the pieces of plastic that are left over after the process is finished. SDI Plastics re-granulate all of our waste material, including the runners. Our team then re-uses this material.

Plastic is durable, flexible and economical to recycle for use in injection moulding and other industrial processes. As well as reducing reliance on landfill, by saving space, recycling plastic also reduces the amount of raw materials needed. This in turn reduces ground pollution and greenhouse gas emissions stemming from the production of new plastic, oil conservation and lastly dramatically reducing our carbon footprint.

SDI Plastics has a well established supply chain that uses recycled raw materials for use in everyday items as well as for more robust and multi-use products. Lists of the main materials we use are:

- Nylon

- PP

- HDPE

- PET

- ABS

This list is continually expanding as the global demand of governments encourage the circular economy approach, which in turn generates greater awareness and momentum.

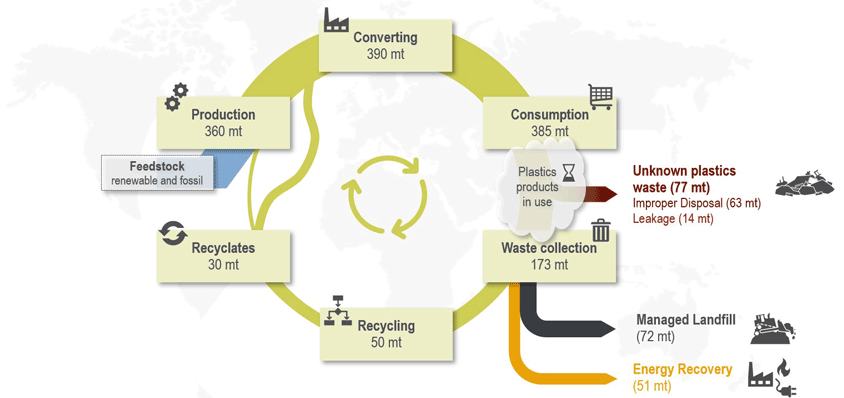

The image below represents the current status of the plastics flow path in the global economy. The aim of the circular economy is to close this loop, identify weaknesses and to allow plastics a second chance rather than being discarded in waste collection facilities, leakages into oceans and sent to landfill.

Preliminary Results of the Global Plastics Flow Study 2018

Source: Global Plastics Flow Study

This study has identified some startling numbers in 2018, which has highlighted the push to resolve this problem. If the global economy continues to operate in this way, this will result in more microplastics than fish. It also highlights how valuable material is lost as it has not been reused or repurposed.

A deeper insight into the statistics

- Production: 360 million tonnes of plastic are produced globally.

- Processing: Added to the 360 million tonnes of new materials are an additional 30 million tonnes of recyclates, therefore a total of 390 million tonnes of plastics are processed annually.

- Post-consumer waste: The total of plastics goods used leads to around 250 million tonnes of consumer-related plastics waste annually.

- Waste management: Of this, 173 million tonnes of plastic waste are collected.

- Environmental littering: 63 million tonnes of plastic waste are disposed of improperly, for example through illegal dumping, and 14 million tonnes are thrown away carelessly (leakage).

Since the creation of this study in 2018, there have been over 350 projects outlined throughout the world to tackle this issue. From recycling challenges, adopting a creek, pallet leakages just to name a few.

If you would like to know more about the various global projects in operation or if you have a product that requires recycled plastic, please contact SDI Plastics. We would love to work with you and make a difference, integrating as much of the circular economy methodology in the injection moulding lifecycle to produce your final product.

Let’s work together

Give us a call to book your free consultation and learn how much value can be added to your business with SDI Plastics by your side.