Services

Manufacturing

Our multiple facilities located in Brisbane, Malaysia and China provide the state of the art product design, toolmaking and injection moulding services catered for your needs.

SDI Plastics offers the complete solution for plastic injection moulding all under one roof from initial concepts, product design and innovation, prototyping, toolmaking, through to the manufacturing of the final product.

As leaders in the industry our key staff members have over 150 years of combined experience, which allows us to work closely with you by taking the time to understand your idea or concept. SDI Plastics have a culture based on entrepreneurial spirit, providing our team with the flexibility and creativity to address the requirements of our clients when designing new products. This includes understanding the product details and functionality, design aesthetics, field use, estimated lifecycles, cost implications and performance specifications of your product. Finally, our team provide assembly, packaging, warehousing and delivery services internationally.

SDI Plastics have the industry knowledge, expertise and are specialists when bringing your product ideas and inventions to life. Our service and delivery has been the pinnacle of our success. Our exceptional workforce produces, package and distribute exceptional products with a proven track record to deliver quality products on time. This has all been streamlined to deliver commercial value and success for our customers.

If you are looking for a forward thinking plastic injection moulder with a wealth of technical experience who will be able to guide you through the entire process of creating your plastic products, including warehousing, distribution and delivery, SDI Plastics can offer you the solution.

Australian manufacturing

SDI Plastics are based in Brisbane, Australia and are a proud producer of Australian made plastic products. Our manufacturing operation supports businesses who wish to manufacture their products onshore and SDI Plastics have an amazing team to support you throughout your journey. Australian manufacturing offers many advantages and allows you to be onsite throughout the entire lifecycle of the manufacturing process. Our team of experts encourage you to be involved and immerse yourself from the initial discovery phase, concept creation, prototype development, toolmaking through to the manufacturing of the final product. There is so much value in seeing your idea transform into reality, and being there every step of the way.

Reshoring and onshoring

The practice of bringing manufacturing services back to Australia from overseas is a trend that has risen over the last few years. SDI Plastics can help support businesses who are seeking to produce their products onshore, offering a risk proof supply chain through reshoring manufacturing services back to Australia. There are many business advantages to consider as manufacturers understand the extended supply chains that go with offshore sourcing, add risks that need to be taken into account. Challenges such as delivering quality products, shipping delays, domestic or international issues can cut off the flow of products and intellectual property may not always be protected in some low cost locations.

With SDI Plastics, bringing your manufacturing back to Australia allows the quality to be better monitored, controlled and maintained locally, with local supply and sustainable manufacturing to produce your products quickly and with ease.

Book your free consultation

Give us a call to book your free consultation for your plastic solutions in Australia, and learn how much value can be added to your business with SDI Plastics by your side.

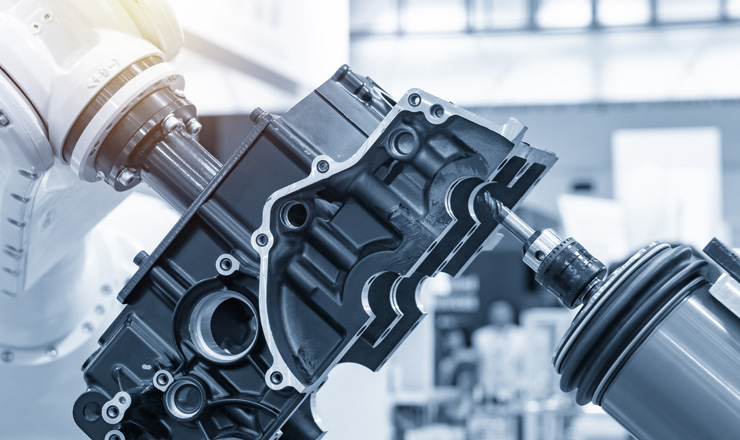

SDI Plastics and industry 4.0

SDI Plastics is constantly innovating and investing in the future of plastics manufacturing by running smarter factories with Industry 4.0. Throughout our operations, our leadership team are investing in smart machinery, robotics and automation, AI, real-time data-driven applications, cloud computing as well as deploying smart technology and devices throughout our manufacturing plants. This is to ensure we are better connected through digitisation, drive quality, increase productivity and create value throughout the production process, whilst providing exceptional customer service.

Our manufacturing operations are using easily integrated production monitoring software to provide real-time access to equipment status. SDI Plastics additionally deploy collaborative robots and robotic arms to complex automated tooling. The integration of robotics in plastic injection moulding has provided many advantages such as consistency, high quality, precision, enhanced features, flexibility, safety, speed and a consistent production cycle time that has reduced onshore labour costs. In summary, SDI Plastics are working towards an approach that uses advanced technologies by building smarter factories. To ensure we remain ahead of the curve, our operational efficiency and enterprise-wide growth are further enhanced by our team who continuously improve our services from design and engineering through to manufacturing and support.

All providing a competitive edge, in today’s changing market.

Research and development

An important part of the advancement for plastics manufacturing is working towards a sustainable future. SDI Plastics have a strong commitment in this area and have established innovative partnerships with key research institutes. SDI Plastics are heavily involved in the field of research and our partnerships give us the flexibility, creativity and test facilities to develop the plastic products of the future, enabling faster production cycles and sustainable plastics. Our work with PHD students and scientists is very exciting and has enabled us to explore and create bio-degradable and eco-friendly plastics.

Our R&D partnerships include working with QUT, UQ, CSIRO and Voestalpine.

Sustainable manufacturing

Sustainable manufacturing is an important approach to industrial production that seeks to minimise the environmental and social impact of the manufacturing process while maximising its economic efficiency. It emphasises the responsible use of resources, energy, and materials, as well as reducing waste and emissions throughout the entire product lifecycle. Sustainable manufacturing employs innovative technologies and practices such as renewable energy sources, recycling, and eco-friendly materials to create products in an environmentally conscious manner. It also strives to enhance worker safety, promote ethical labour practices, and engage with local communities.

At SDI Plastics, our leadership team fosters a sustainable approach to manufacturing. We are committed to staying at the forefront of this environmental movement, offering our clients sustainable options that align with our values and contribute to a greener future. From ideation through to packaging and delivery, we’re dedicated to incorporating eco-friendly practices throughout our operations.

Sustainable manufacturing is a pivotal step towards building a more responsible and prosperous future.

Assembly, packaging, warehousing and delivery

SDI Plastics offer a holistic solution to your manufacturing needs. Our team provide custom assembly service across a wide range of products, and complete in house assembly of products or partial assembly of products, depending on your requirements. As part of our commitment to providing a quality service, our team additionally provide packaging and labelling services which are custom made and tailored to your needs. This can ultimately save you time and reduce additional costs in the long run, as the service is provided onsite at our manufacturing and warehousing facilities.

Our attention to detail is unparalleled within our industry and we take pride in every single consignment, delivering on quality and dispatched from our distribution and warehousing operations in Australia and Malaysia. Continuously investing in our team training and development here at SDI Plastics, we believe ‘only the best is good enough!’ and that a team that is kept up to date can exceed customer expectations.

Have a project you think can’t be done?

Contact us to see how SDI Plastics can make it possible.

Let’s work together

Give us a call to book your free consultation and learn how much value can be added to your business with SDI Plastics by you side.